Greater than the sum of its parts

A framework for grain composition of commodity crops

Farms in production agriculture are often described as, “a factory with no roof.”

A better metaphor is, “a mine that harnesses millions of workhorses called ‘plants.’”

Crops like corn and soybeans produce raw materials that are manufactured into thousands of other products.

Those raw materials are carbohydrates, protein, and oil. The fact that corn and soybeans are broken down into these building blocks make the abundance and absurdity of the agricultural value chain possible; that every year trillions of plants are grown to make everything from ethanol to Otter Pops.

Today we will walk through how something as tiny as the molecules in a seed shape global supply chains, and what this idea might hint about our agricultural future.

Let’s dig in!

Grain and oilseed composition

A whopping 45% of acres that are farmed in the US grow just two crops: corn and soybeans. The vast majority of these nearly 180 million acres are not growing corn-on-the-cob for your summer barbecue or edamame at your favorite sushi joint.

Instead, these acres churn out almost 16 billion bushels of corn grain and 4 billion bushels of soybeans (like those pictured below) every year in the US alone.

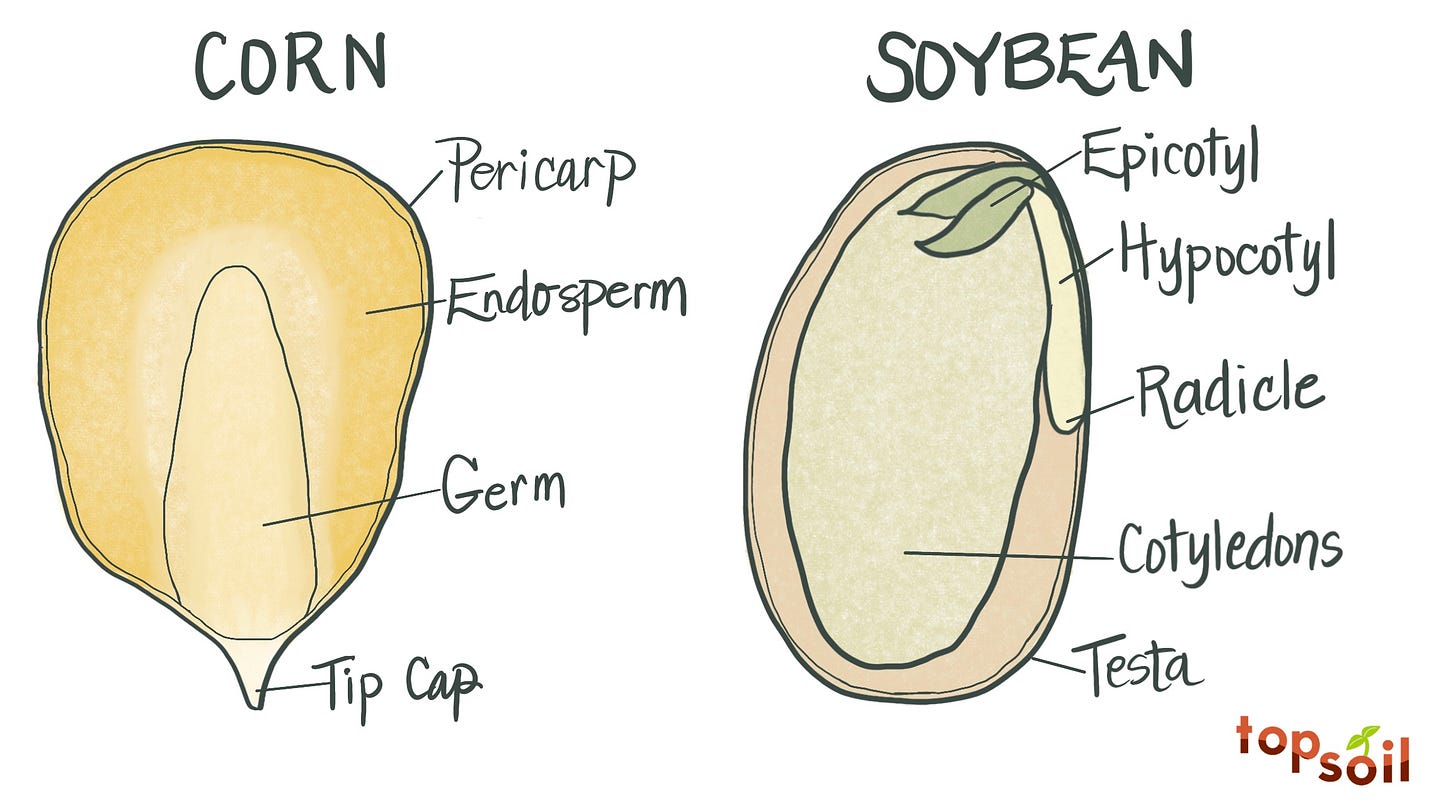

Before we get into the corn-and-soybeans-as-raw-materials line of thinking, it’s worth remembering that each kernel and soybean is a seed – a perfect package to grow a new plant and start the cycle of life all over.

With this botanical lens, it makes sense that each part of the seed has a purpose honed over hundreds of millions of years of evolution to ensure reproduction. Humans have only been involved for the past 10,000 years or so to make these seeds serve our purposes of food, feed, and fuel.

Each tiny part of the seed serves a purpose. There is a protective outer coating (the pericarp or the testa). The germ or embryo (the epicotyl, hypocotyl, and radicle in the soybean illustration) holds the genetic information for the new seedling. Once the seed germinates, it will use energy stored in the endosperm or cotyledons to grow before photosynthesis takes off.

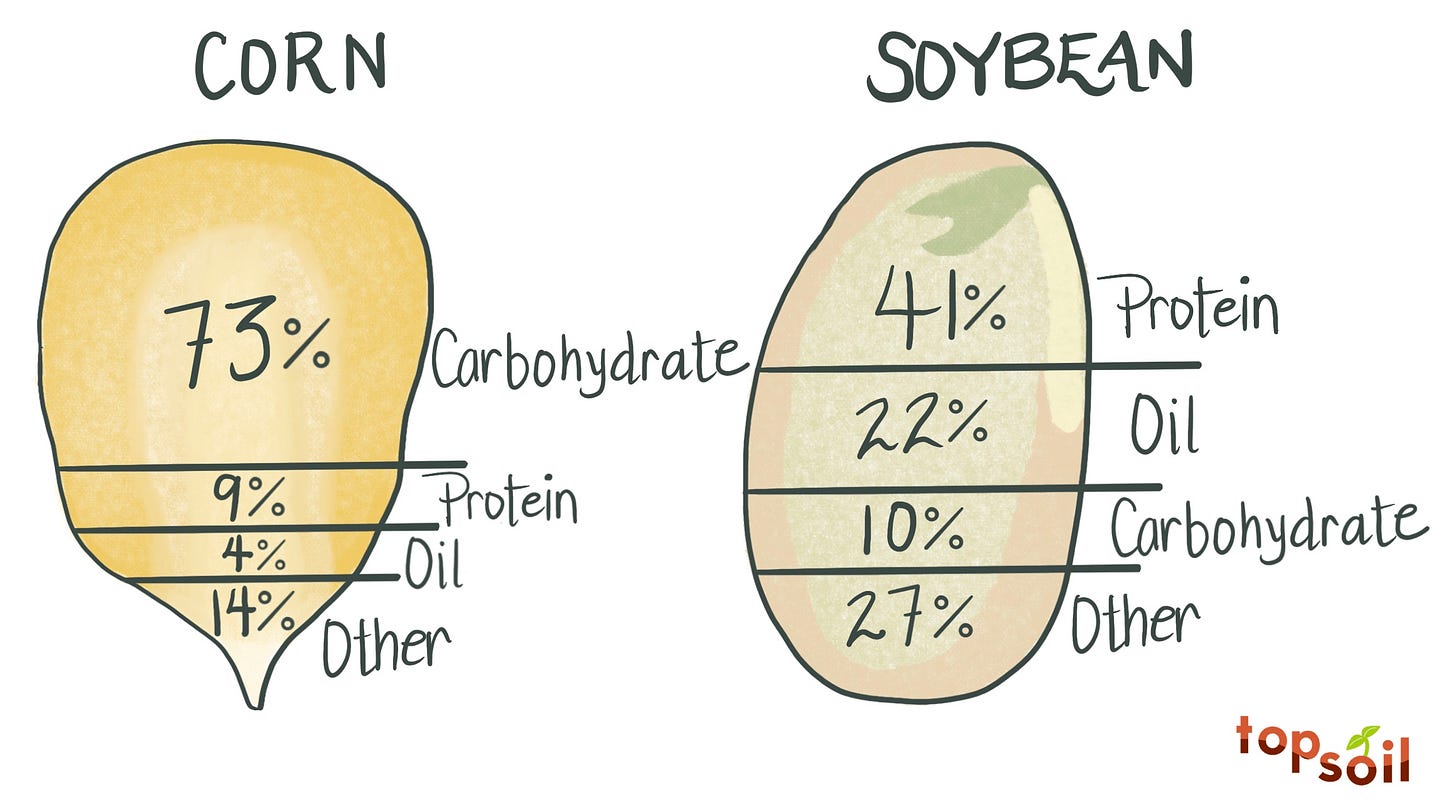

Now, let’s take a closer look at the chemical composition of each kernel of corn and soybean:

When you see the percentages of protein, carbohydrate, and oil, don’t think of it like a Nutrition Facts label on a snack you’re considering munching on. I repeat: these types of field corn and soybeans are overwhelmingly not directly consumed by humans. Instead, think of the protein, carbohydrates, and oil as building blocks that are broken down and re-assembled into new products through processing.

In an ultra-simplified description that may make the chemists among you roll your eyes, you can think of the following:

Carbohydrates = easily accessible energy

Oil = very dense energy

Protein = building blocks for tissue

Breaking down to build up

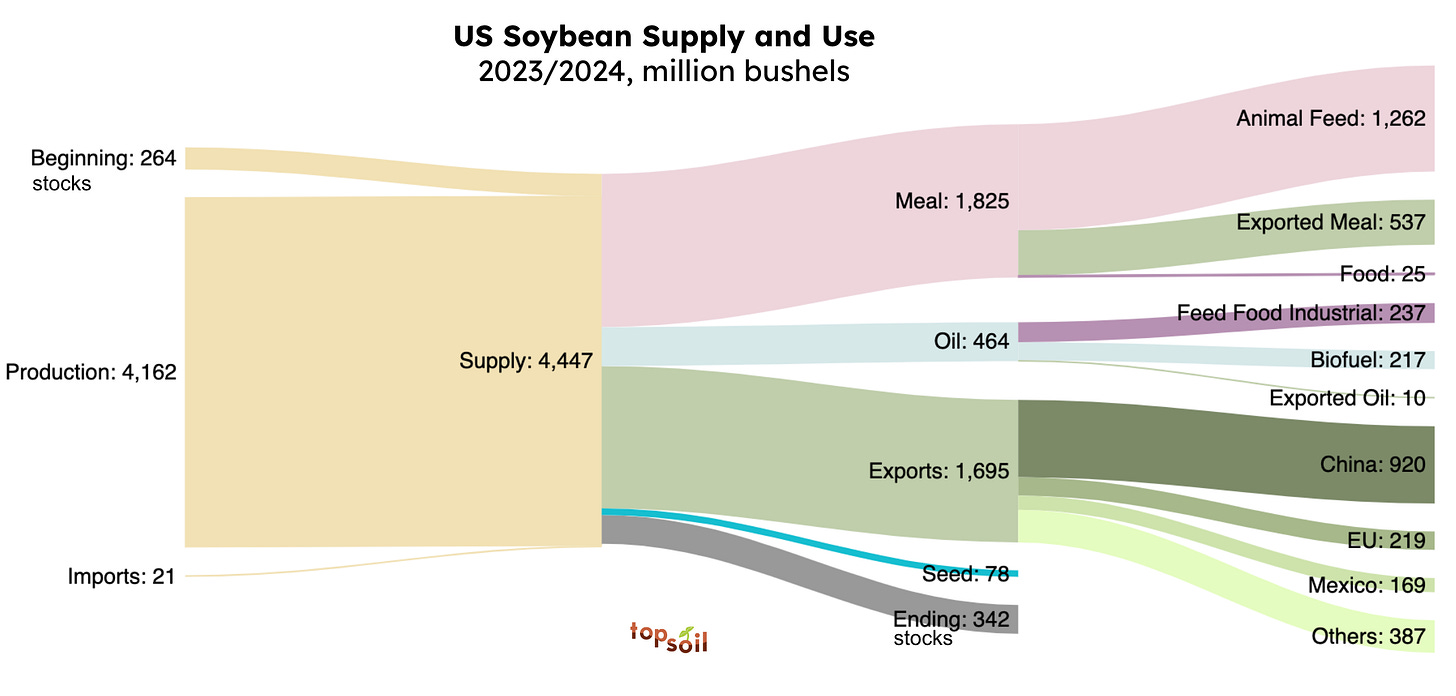

After harvesting, farmers haul the corn and soybeans to buyers. Buyers either export or process the grain. Today, we’re talking about the processing piece of the puzzle. Processing is where the annual cropping cycle, with one harvest per year, meets the steady mechanical beat of a factory that must be fed every day of the year. Vast amounts of storage connect these two cycles.

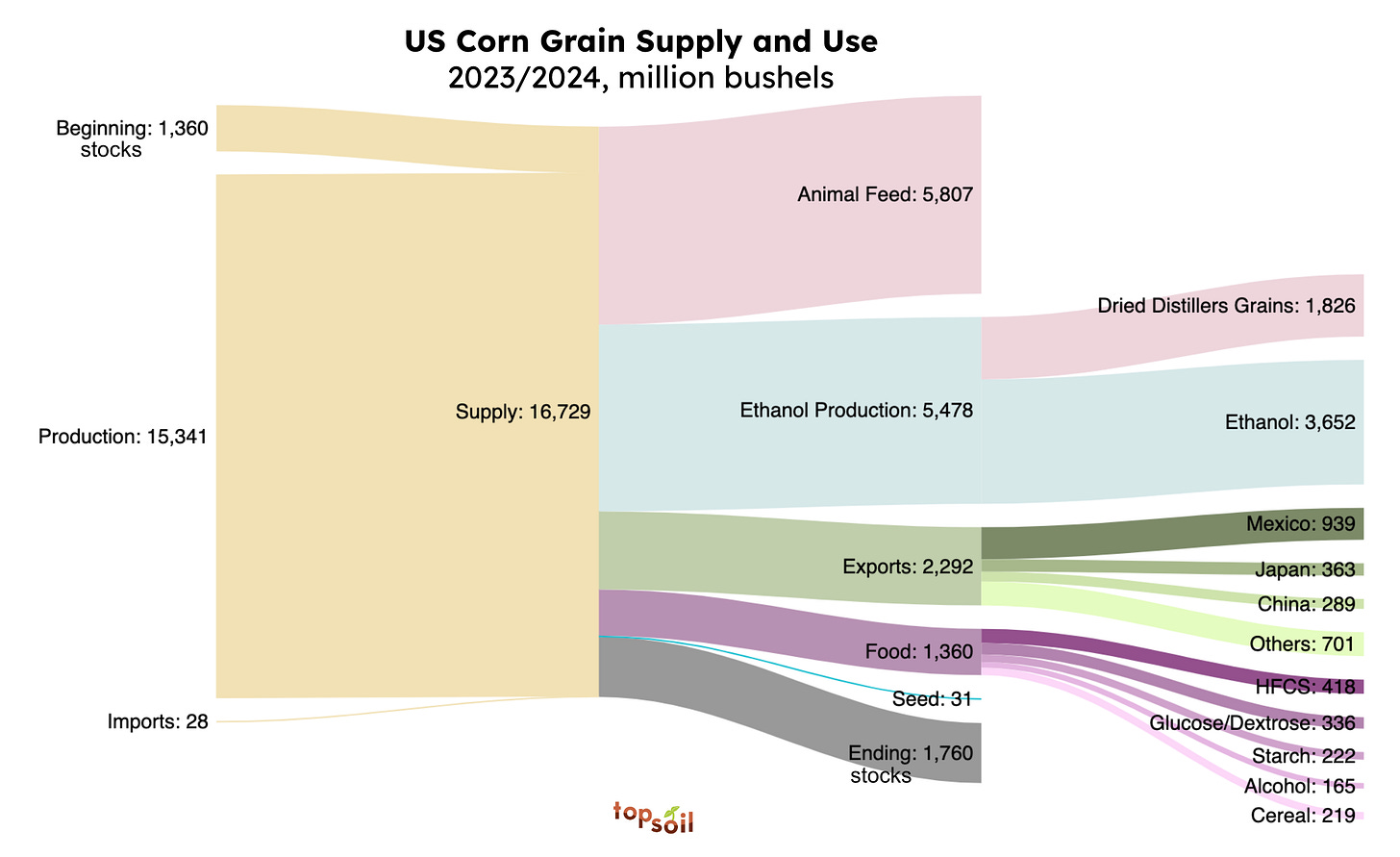

Through processing, the grain is broken down and fed to livestock, or converted into fuel or other ingredients:

Roughly 75% of corn that is processed is dry-milled and 25% wet-milled. Dry-milling produces ethanol and dried distillers grains which are fed to livestock. Wet-milling produces a greater variety of products (like corn oil and high fructose corn syrup). In either case, the corn is broken down into its chemical components through a series of steps, including grinding, steeping in acidic solution (wet-milling), fermentation, cooking, distilling, and refining.

Soybeans are split into two main ingredients: oil and protein flakes. After the soybeans are cleaned, cracked, dehulled, heated, rolled, and soaked in a solvent, the oil is separated and further refined. The remaining flakes are chock full of protein and are dried, toasted, and ground to become livestock feed.

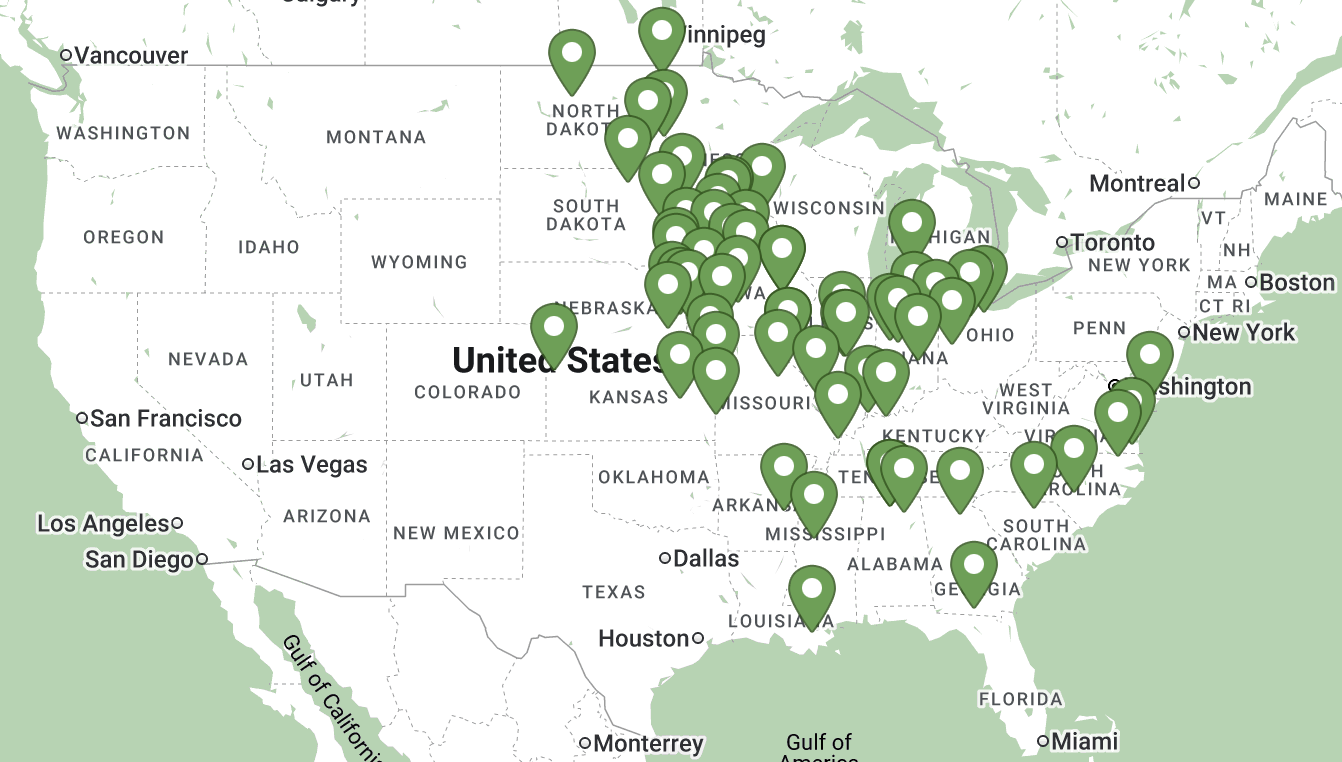

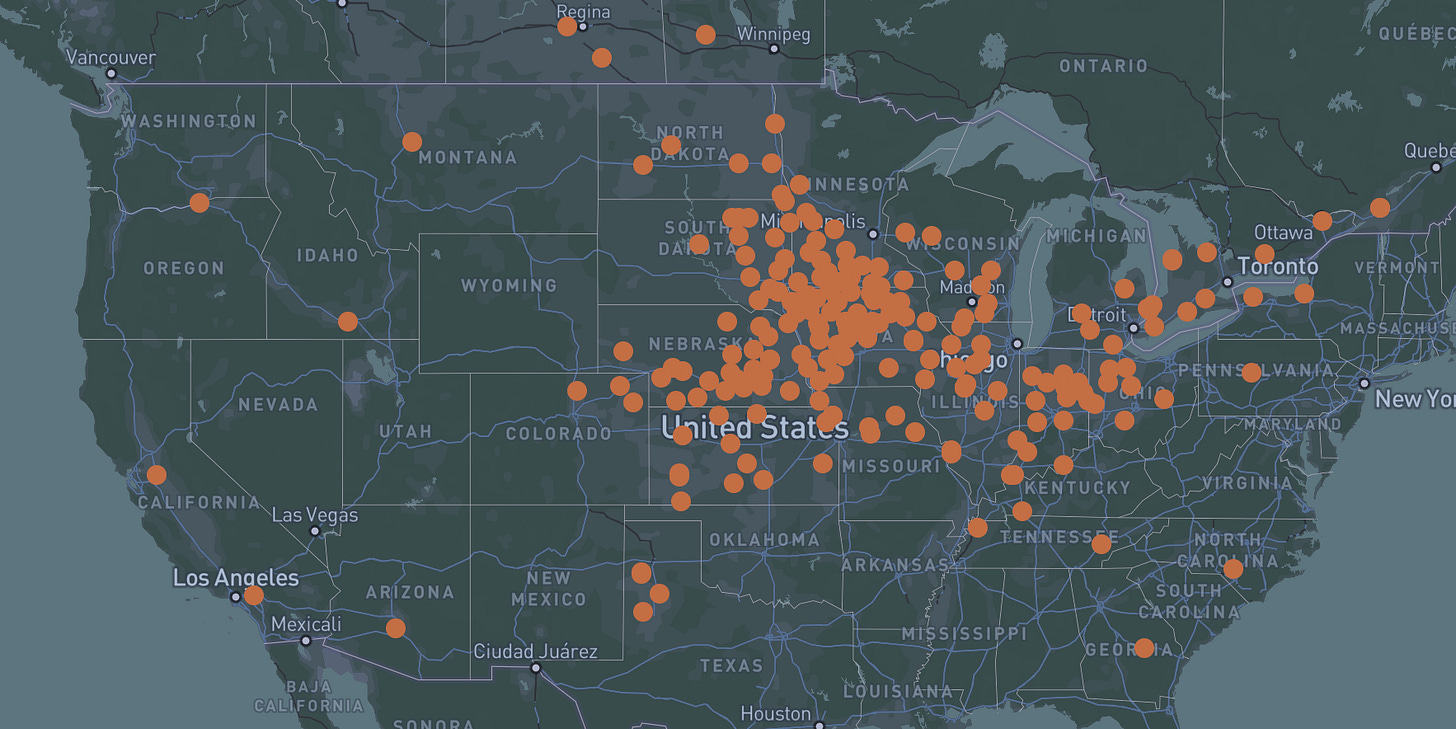

Billions of dollars have been invested in building the storage, transportation, and processing infrastructure for corn and soybeans. There are over 60 soybean processing facilities in the US and over 200 facilities that process corn, most of which are based near where the crop is grown in the Midwest:

Ever-changing over time and place

The chemical composition of corn and soybeans is not like an iron law of physics. It’s more similar to how you might think of yield – the average corn yield is around 200 bushels, but averages are just that; they don’t hold true everywhere.

If you walked into a field of corn and sampled the chemical composition from one corner to the other, you’d get different readings throughout the field. The amount of protein, carbohydrates, and oil varies field to field, county to county, and beyond. A field is a living, breathing, system with uncountable variables above and below the ground. Like yield, composition is shaped by genetics, environment, and management practices.

Generation of crop after crop, the amounts of protein, carbohydrate, and oil have shifted over the years based on market demand. Processors downstream signal to plant breeders upstream what is more or less valuable. Crops can even be bred to produce greater quantities of specific types of carbohydrates or protein (like lysine or prolamin) that are easier for livestock to digest.

For example, your dad or grandad’s corn from the 1970’s contained about 13% less carbohydrate than today’s varieties of field corn. Since the Renewable Fuel Standard was passed in 2005 and demand for corn for ethanol skyrocketed, field corn has been bred to produce a higher percentage of carbohydrate and oil.

Processing ensures that these biological variables are smoothed out to produce consistent ingredients that can be manufactured into thousands of other products.

Greater than the sum of its parts?

I’ll admit — there’s something a little icky about describing farms as ‘mines’ for raw materials. It conjures up extraction, uniformity, and a faceless interchangeability that is all a bit unsettling.

However, this assumption, that commodity crops are only as valuable as their molecular building blocks, explains a lot about how our modern agricultural system works. It is a key feature that makes the global agricultural value chain modular, consistent, and ceaselessly hungering for new sources of demand.

Focusing on just three macronutrients also makes it easy to miss that within each kernel of corn, there are over 150 unique chemical compounds. 150! And in sweet corn, that number clocks in at over 500. There is depth and complexity in every seed that is not fully captured by this simple framework.

The seeds of the future

I want to be very clear. In 2025, farmers of the vast majority of row crop acres in the world are paid primarily by one metric: yield.

After quality standards are met, it’s a volume game. Grain buyers are not measuring the protein, starch, or oil content of each load of corn and soybeans. Moisture is accounted for simply because that can shift volume. More bushels equals more money. Period.

However, whether or not you think of a kernel of corn as nothing more than the molecules it contains, you can imagine a future that is either mildly or wildly different from the agriculture we know today:

Paying farmers based on grain composition, not just yield. This happens in some cases today. For example, farmers can be paid a premium for higher protein wheat, or for growing special varieties of soybeans with unique oil profiles (like high oleic). “Nutritional density” might be the hottest two words in 2025 after “artificial intelligence,” and this shift would be a step in that direction.

Farming specific molecules with plants. We’ve invested heavily in corn and soybeans as the supremely productive plant chassis for producing high yield. Think of “molecular farming” as genetically engineering plants, so they can produce specialized proteins like casein (stuff that makes cheese melty), antibodies for vaccines, or pharmaceuticals.

Phytomining. This concept makes “farms as mines” a reality. Certain plants can draw up specific compounds from the soil. Then, the plant biomass is processed to isolate those compounds, like nickel or rare earth minerals.

Inventing new crops. As different ratios of protein/carbohydrate/oil become desirable, plant breeders and plant scientists can develop new crops. Although rapeseed has been grown for thousands of years, in the 1970’s, canola was developed by plant breeders to have a more favorable fatty-acid profile for human consumption. Canola is now grown on over 22 million acres around the world.

Cutting out the middlemen (plants). If you go deep down the rabbit hole of we-only-farm-for-the-molecules, you might imagine some odd future scenarios. Like asking, why do we even need plants? What if there were a way, like artificial photosynthesis, that carbon dioxide could be transformed into protein, oil, and carbohydrates without farming 180 million acres? This is a good thought exercise to consider the purpose of farming beyond just producing molecules.

The fact that corn and soybeans are broken down into building blocks that can be used in thousands of other products means that farms today are inextricably tied to more industries and supply chains than ever. I bet if you told the average person in 1975, when practically no corn was used to make ethanol, that 50 years in the future, a third of all corn grown in the US will be used for fuel, they would not have believed you.

What might be possible in the next 50 years?

Topsoil is handcrafted just for you by Ariel Patton. Complete sources can be found here. All views expressed and any errors in this newsletter are my own.

If Topsoil has helped you understand the fascinating world of agriculture a little better, please like using the heart button below, subscribe, or share with an ag-curious friend!

Another crystal clear explanation of commodity ag. Thank you for the insights!

Love it, another banger! 🙌🏾