Happy New Year! Writing this newsletter has brought me so much joy, learning and connection in 2023 – I want to personally thank you for supporting Topsoil over the past year.

One of the most beautiful things about agriculture is that it is infinitely vast, spanning every culture and intersecting with every domain you can think of. Something I’ve grown to appreciate is that one person will never know the full breadth and depth of agriculture.

As we kick off 2024, I am excited to share something new that I’ve been working on.

Through Topsoil, I love sharing what I know from my own experience and researching data. Now, I want to share with you all my secret weapon for learning – talking with folks across the industry with different perspectives and insights.

Over the past month, I’ve been experimenting with turning expert conversations into simple Topsoil frameworks at just the right depth. I’m thrilled to share this first attempt with you today!

I had the opportunity to sit down with Greg Chiocco, a 20+ year veteran in agriculture equipment and agtech and current VP of Product at FarmWise. Greg is a mechanical engineer by training and spent the early 2000s at Trimble and Topcon, companies that shaped precision agriculture as we know it today. Prior to leading product at FarmWise, Greg held product leadership roles at the Climate Corporation, Zoox, Granular and Mineral, which has given him a front row seat in shaping how technology is applied in agriculture.

Managing field variability at scale

When I (Ariel) started working in agriculture, I heard the words “precision ag” applied to many seemingly different things. Variable rate fertilizer? Precision ag. Scouting using drones? Precision ag. Yield maps? Precision ag.

I had the sense that it was loosely tied to machinery and farm data, but there wasn’t necessarily a clear-cut dictionary definition that resonated. It is one of those loosely defined, I-know-it-when-I-see-it kind of terms: agriculture, but make it precise.

Greg had a helpful way of defining precision agriculture: “When you think of agriculture, it’s the tractor, the implement, the on-the-ground action that you’re taking. Precision agriculture is that additional layer of technology that goes on top of those machines.”

Because farming takes place outdoors in the real environment, every field is different. Within each field, there is also a huge amount of variability. For example, the soil type in one corner might be heavier clay than the center of the field. There may be drainage issues in certain patches. The field might be on a sloping hill. You get the idea.

Now, imagine a tractor rolling through the field. Without precision agriculture, the tractor will treat every part of the field the same. Planting at the same seeding density, no matter the quality of the soil. Applying fertilizer at the same rate, no matter if some areas are more nutrient-poor than others. Spraying herbicide from the same height, even if the ground is rolling.

With precision agriculture, the equipment instead automatically adjusts to the variability within a field. Let’s look at planting corn as an example. Modern planters (a piece of equipment that can cost over $250k designed for – you guessed it – planting) combine many pieces of technology to make variable rate seeding possible.

First, data is collected for each field using sensors: yield maps from previous years, soil type, and topography to name a few. This data is loaded into software that divides the field geographically into “management zones,” with each zone being prescribed a different seeding rate. Typically, more productive areas of the field are planted more densely with corn. This rate can vary widely, from 20,000 seeds per acre to more than 40,000 seeds per acre.

Spring rolls around, which it means it’s go time to get the corn seed planted in the ground. The variable rate seeding prescription generated by the software above is loaded into the computer monitor inside the planter. As the planter moves across the field, the GPS receiver lets the planter know exactly where it is in the field, within a meter (and in some cases down to the inch!). The planter meters more or less corn seed depending on its location in the field. Voilà! Instead of one average seeding rate across the entire field, each zone is planted with the optimal number of seeds to hit a farmer’s yield target.

Variable rate seeding is just one example of the incredible choreography of equipment, software, inputs, and people that make up precision agriculture. But, as Greg points out, it wasn’t always this way.

Precision agriculture can mean many, many things

It’s helpful to go back to the origins of what we think of as modern precision agriculture.

Greg shares, in the 1990’s, if you mentioned the term “precision agriculture,” you’d likely be met with a blank stare. The precision agriculture that we would recognize today came on the scene as a result of a couple technologies that unlocked something new when combined: readily available and affordable high-precision GPS and sensors on a combine harvester (specifically impact plate sensors and moisture sensors).

“Yield maps are where precision ag began.” (Side note: any quotes are from Greg unless otherwise noted) Farmers could suddenly see their yield within a field, as their combine moved across the field, for their entire farm operation. With this information, farmers had a scorecard of how different parts of a field performed to inform decisions for the next year. Precision agriculture was born.

Now, precision agriculture has become an “all encompassing term for many, many things” and can influence farming at every step of each season.

Precision agriculture creates real value

There are some obvious benefits to more precise, targeted action:

Improving farmers’ bottom lines by increasing yields or reducing costs. “The value proposition of precision agriculture is crystal clear. You’re building a thing that gets used in the dirt, on the ground, in the soil everyday. And with farmers being as pragmatic as they are, if it didn’t bring them value, they wouldn’t use it. Farming isn’t a high margin profession, so it needs to be valuable.” How much can precision agriculture help financially? Of course this depends on the specific technology and what the farm was doing before, but studies in US Midwestern corn and soybean farmers show a perceived increase of almost $90/acre (which can quickly add up when farming across thousands of acres).

Reducing friction and saving time. Greg shared stories of other intangibles that farmers love about precision agriculture, like getting time back in their day or being able to outsource more: “Many farmers mention the ‘convenience factor.’ They could check their email and commodities prices while in the [tractor] cab instead of having to spend hours in the office. Before guidance [auto steer], it was rare that a farmer would put a hired person in the planter, because it was too easy to get wrong. With guidance, they could trust a hired person and spend a little more time on other things on the farm or with their family.”

Doing more with less for better environmental sustainability. Precision agriculture delivers on the current industry rallying cry of “more with less” by reducing the amount of inputs that are needed for the same (or better) results. Even before AI-powered spot spray solutions, innovations like section control (being able to turn sections of a farming implement on and off) reduced overlaps and skips when planting or applying inputs (illustrated below).

Addressing labor and humanitarian challenges. Farms often struggle to find and afford labor. Beyond simply ensuring there are folks to work in the field, Greg highlights another difficulty that precision agriculture can help address – the work itself can often be highly undesirable for employees: “I watched a crew of 40 people crawl on their hands and knees through a spinach field because that’s how you harvest spinach. It’s horrible, backbreaking work.”

Making new things possible. One example is conducting field trials at scale. Any field has dozens of variables, like soil type, weather, variety of crop planted, specific inputs applied, and on and on. It is difficult to tease apart which make a difference to crop yield. With precision agriculture, more variables can be controlled and measured, and data can be gathered across more acres. Beyond research institutions, farmers themselves can run experiments to better understand what works for their own farm.

…But it’s no silver bullet

Despite his own dedicated career in precision agriculture and the benefits above, Greg warns “It’s not going to solve all of agriculture’s problems. I can’t stress enough that there’s no silver bullet in agriculture.” There are several nuances and limitations.

Not only is there variability within and across fields; every geography and crop is unique. This makes it tough to scale any given precision agriculture solution globally. Just because a tool works in one region for one crop does not mean that it will work everywhere.

Greg shared an example from working on equipment in Western Europe (EU). Farms and fields in the EU tend to be relatively small (the average farm size in the EU is 43 acres compared to 445 acres in the US). Farms in the EU also must comply with stricter regulation. As a result, many EU precision agriculture solutions emphasize easy recordkeeping and maneuverability in small, irregular shaped fields — which isn’t necessarily the same wishlist from farmers in the US, Latin America, or elsewhere.

Spoken like a true engineer, Greg notes that “every additional layer of complexity is another potential point of failure." Many systems must work together for precision agriculture to deliver results. Like any technology that meets an unforgiving world of dust, weather, or patchy internet, this doesn’t happen seamlessly every time.

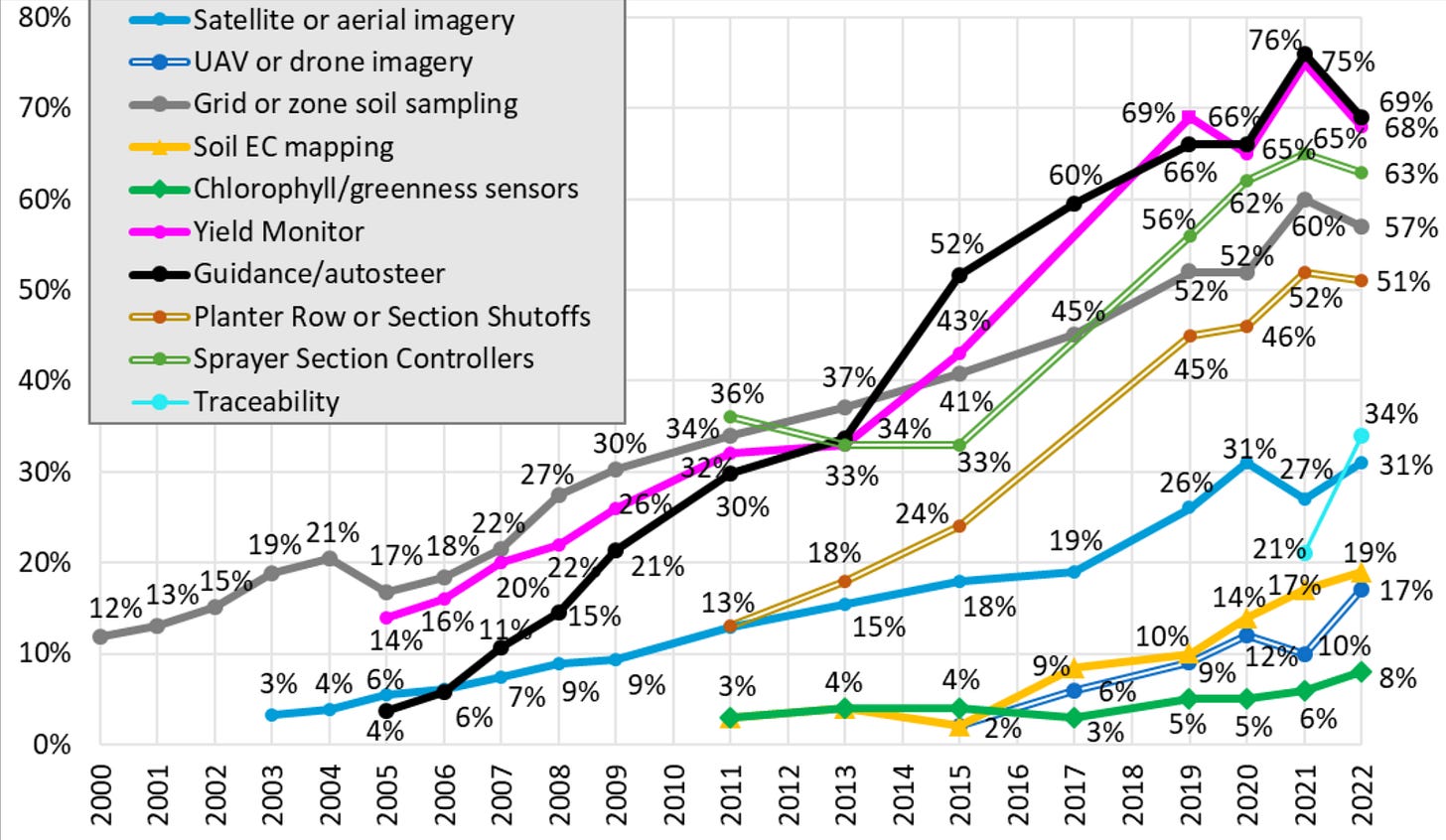

Finally, “even if the technology is exceptionally valuable, it still takes time for it to be adopted in an agricultural setting.” Even auto steer, the poster child of successful technology adoption in agriculture, is used by less than 80% of US Midwestern farms. And, it took 15 years to get to that level of popularity!

But, one exciting observation that Greg had is that this may be changing.

“Back in the day, getting people to change their practices for the sake of technology was really hard. They wanted to jam precision ag into their current farming practices to make their life easier. Now, it seems that farmers are embracing technology to the point that they are willing to change their farming practices to adopt the technology because it makes their life easier. We’re seeing people change their watering schedules or field configurations to use a robotic weeder or autothinner or some other technology.”

Next wave of precision agriculture

Despite the funding winter we are in today, there are reasons to remain bullish on precision agriculture.

For one, Greg shares that over his career, it has “gotten so much easier to apply these technologies. We are now doing a lot more system integration instead of building the systems from scratch. This makes it so we can build faster and it’s harder to screw things up.”

As an example, imagine an equipment company that is creating an automated tractor. Instead of the engineers building a custom computer from the ground up with all the right processors to control the tractor, companies like NVIDIA now offer out-of-the box chips that can simply be integrated into the equipment. Agriculture companies can focus on what they do best and innovate faster.

This is similar to the way that Amazon Web Services provides the behind-the-scenes cloud computing and storage so companies don’t have to build their own on-premise servers. Each company can now focus on their own special sauce, and not on building baseline infrastructure every time they want to create a new product.

Finally, precision agriculture is getting more and more precise.

Remember how GPS and combine sensors were the underlying technologies that made precision agriculture possible? Since the 1990’s, there have been many new “enabling” technologies: new types of sensors, better data storage, faster connectivity, and improvements in hardware to name a few.

Today, we are entering a new exciting era: “once you start to apply artificial intelligence (AI) and computer vision to precision ag, the possibilities are endless.” Among several other possibilities, AI and computer vision can help equipment get even more targeted in the field than with GPS alone. This brings us closer to a future of real-time, or even predictive, plant-by-plant management at scale.

Thank you for reading today’s newsletter!

Beyond creating the Topsoil newsletter, another highlight from 2023 has been chatting with Tim and Tyler Nuss on The Modern Acre Podcast and learning more about their farm. Last month we talked all about the farm team, which you can listen to here!

Topsoil is handcrafted just for you by Ariel Patton. A sincere thank you to Greg Chiocco for sharing your knowledge with me and editing. Complete sources can be found here. All views expressed and any errors in this newsletter are my own.

How did you feel about this monthly edition of Topsoil? Click below to let me know!

Great overview Ariel. A lot of good initiatives on this way. While we still have a lack of professionals to expand the Precision Ag adoption, we are having several companies that are creating solutions to better understand the ecosystem and to better 4R's fundamentals.